We are a professional geosynthetic materials manufacturer with a dedicated HDPE geocell production line. We can provide customers with high-quality HDPE geocell products at factory prices. We guarantee that our products:

ASTM/ISO tested materials, stable quality

Wholesale & OEM supply, global export

Engineering support: selection, BOQ, submittals, layout

Fast lead times with consistent production capacity

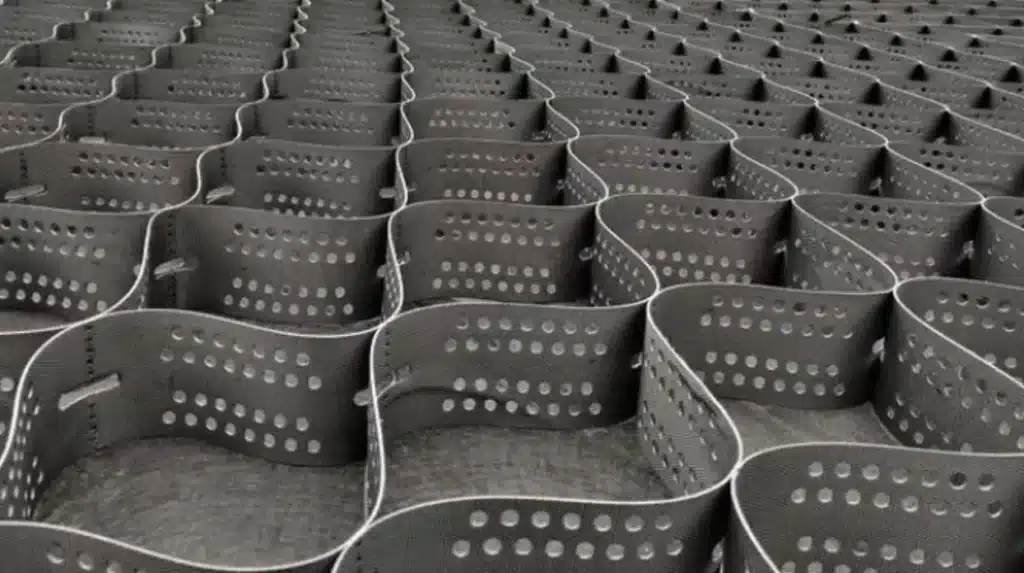

Product Name: HDPE Geocell

Cell Depth :50, 75, 100, 125, 150, 200mm

Weld Spacing: 330, 356, 400, 445, 660, 712mm

Thickness(Textured): 1.5, 1.52, 1.6mm

Thickness(Smooth): 1.1, 1.2mm

Colour: Black, Sandy, Green

Standard: ASTM, ISO

- +86 18661683263

- +86 17660616628

- info@geosyntheticsmanufacturer.com

We are a trusted HDPE geocell manufacturer and wholesale supplier of advanced soil-stabilization and erosion-control solutions, exporting worldwide for roads, embankments, and slope protection. Our ASTM-standard factory engineers each geocell from high-density polyethylene to meet international benchmarks for strength, UV resistance, and long service life—delivering durable, flexible, cost-effective performance. For Europe, we offer Geocell HDPE verkaufen with reliable supply and direct factory pricing. With advanced technology and strict QC, our geocells stand out for stability, efficiency, and sustainability.

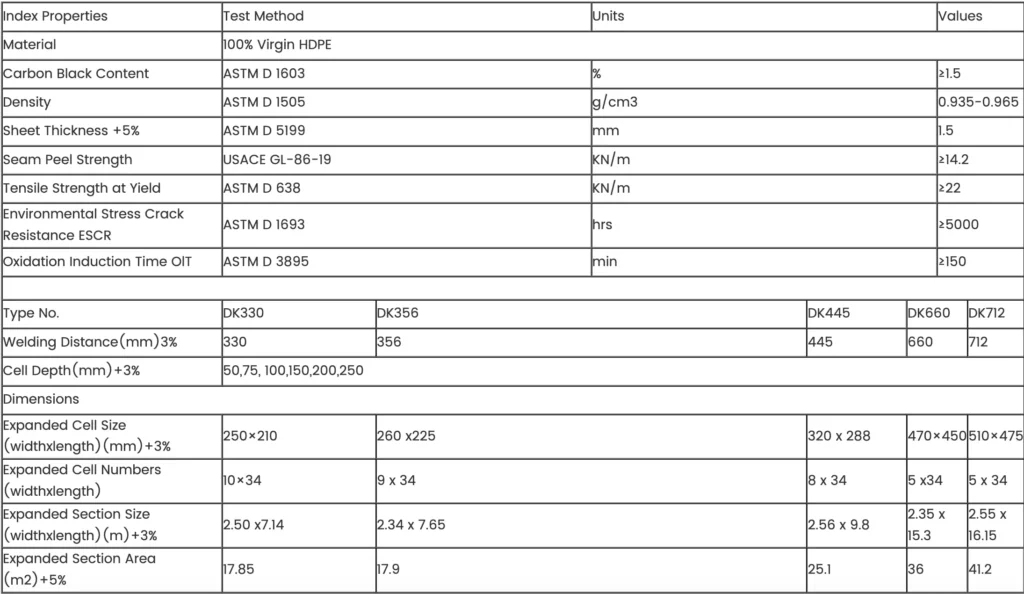

Specifications Of Hdpe Geocell Produced By The Company

HDPE Geocell Production Process

At MJY, our HDPE geocell products are made from high-quality raw materials sourced from globally renowned suppliers. As one of the trusted HDPE geocell manufacturers, we utilize advanced blown film and calendering processes to ensure consistent product quality. During production, polyethylene resin is heated to its melting point in the extruder barrel, then passed through a precision filter and die to form a continuous tubular film, which is then vertically stretched by pressure rollers.

Our company employs a professional cooling system to maintain uniform HDPE geocell thickness, ensuring that all manufactured HDPE geocells meet international standards.

Raw Material Storage

Raw Material Feeding

Sheet Extruding & Embossing

Strips Cutting

Perforating

Ultrasonic Welding

100% Inspection Before Packing

Packing

Prepare subgrade (trim ruts; proof-roll if feasible)

Place separator geotextile (laps 300–500 mm)

Expand & anchor geocell (stakes/pins; align panels)

Infill with specified aggregate/soil (avoid trafficking on empty cells)

Compact to target density; proceed lift-by-lift on slopes

Roads & Yards

base/subbase confinement, reduced rutting, thinner sections

Driveways & Parking

long-life foundations with lower maintenance

Retaining Walls

stable backfill layers, improved facing performance

Slope Protection

soil/vegetation anchoring, rock/riprap interlock

Ports, Mining & Oil/Gas

haul roads, heap leach platforms (as needed), berms

Client Testimonials

Our clients love us, here are a few of their quotes.

FAQ

What is an HDPE Textured and Perforated Geocell?

An HDPE textured and perforated geocell is a three-dimensional honeycomb-like structure made from high-density polyethylene. The textured surface increases friction with soil, while the perforations allow for water drainage and pressure equalization. This combination makes it ideal for soil stabilization, erosion control, and load support applications.

What are the main advantages of using textured and perforated geocells?

Improved friction: The textured surface enhances soil confinement.

Better drainage: Perforations allow water to pass through, reducing hydrostatic pressure.

Higher stability: Helps prevent soil movement on slopes and soft ground.

Durability: Resistant to UV radiation, chemicals, and extreme weather.

Where can HDPE Textured and Perforated Geocells be used?

These geocells are commonly used in:

Road and railway base reinforcement

Slope and embankment stabilization

Retaining walls and channel protection

Erosion control near rivers, lakes, and coastlines

Load-bearing platforms in construction projects

How does the perforation improve geocell performance?

The perforations in the geocell walls allow water to drain freely, which reduces pore water pressure and prevents soil weakening. At the same time, they improve the interlocking between soil and geocell, enhancing overall load distribution and long-term stability of the structure.

How long can HDPE Textured and Perforated Geocells last?

When manufactured from high-quality HDPE resin, these geocells can last 20 years or more depending on soil conditions and UV exposure. They maintain strength and flexibility over time, making them a cost-effective and long-term soil reinforcement solution.

Contact Us

- +86 18661683263

- +86 18661683263

- info@geosyntheticsmanufacturer.com