Can You Pour Concrete Over Geocell?

Short answer: Yes—when U design it right. A compacted subgrade, nonwoven separator, properly anchored geocell ground grid (filled and compacted), a thin blinding layer, and then the slab with correct joints/drainage create a stiff, durable section. Done to spec, concrete-over-geocell grid cuts base thickness, limits pumping/rutting, and improves freeze–thaw performance.

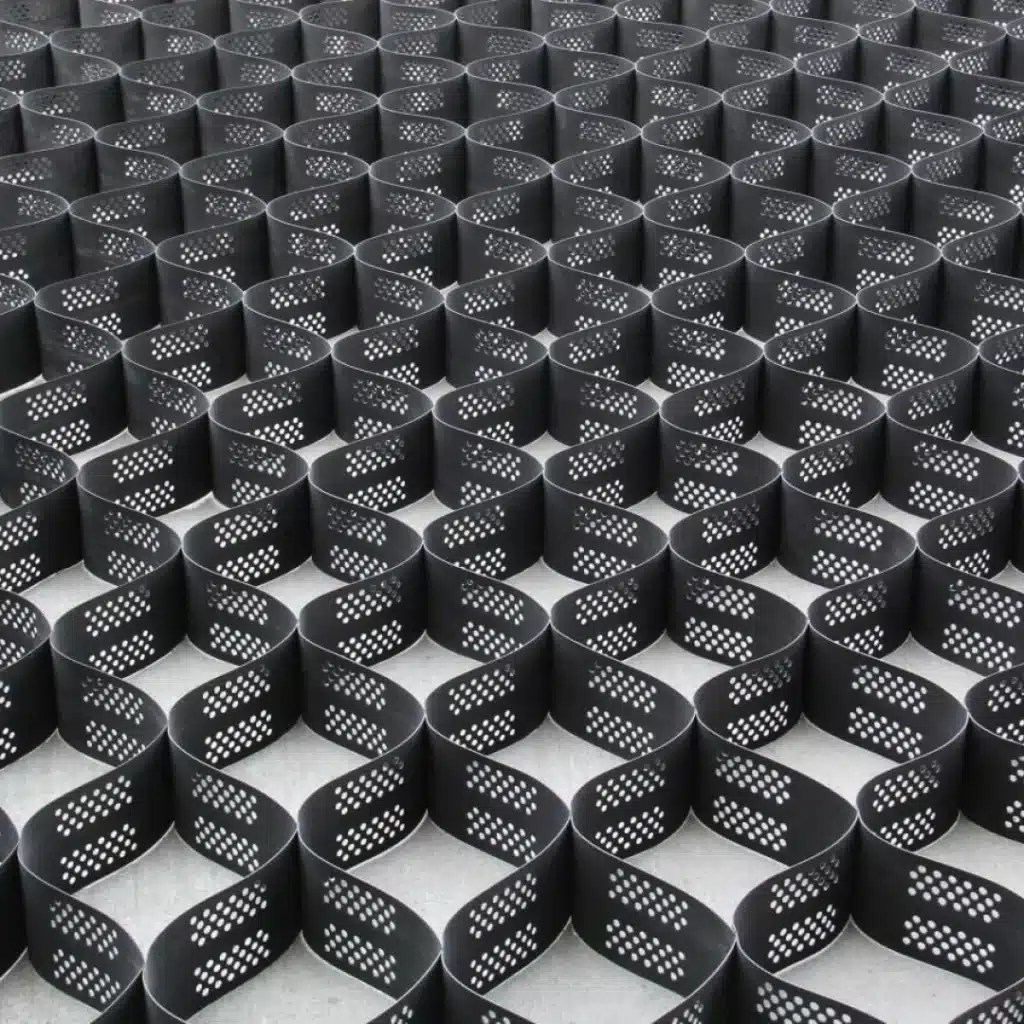

What “Concrete Over Geocell” Really Means

A geo cell grid acts as a cellular confinement layer beneath the slab. The cells confine graded aggregate so loads spread laterally, not down. The slab rides on a uniform, high-modulus platform—less differential settlement, fewer reflective cracks.

- Where it fits: weak subgrades, high groundwater, frost-susceptible soils, remote drive lanes, cul-de-sac bulbs, utility yards, equipment pads.

- Common materials: UV-stabilized HDPE geo cell ground grid, nonwoven geotextile separator, well-graded crushed stone infill, 20–40 mm sand/fines blinding, steel or fiber-reinforced concrete slab.

When It’s a Good Idea vs. When to Rethink

Use geocell + concrete when U need:

- A thinner total section without sacrificing bearing capacity.

- Better performance over variable subgrades (bridging soft spots).

- Faster construction with fewer import volumes than deep unconfined base.

- Added protection against freeze–thaw heave and fines pumping.

Re-evaluate if:

- U have high-velocity hydraulic channels needing anchored structural slabs.

- Extreme point loads demand a formal pavement/slab-on-grade design with higher thickness and doweled joints.

- Chemical/thermal exposure calls for special concrete or liners—confirm compatibility and details.

Design Checklist (What to Lock Before U Pour)

- Subgrade target: proof-rolled, 1–2% crossfall for drainage, compacted (92–95% Mod/Proctor typical).

- Separator: nonwoven geotextile across the entire footprint to stop fines migration.

- Cell height: 4” for light duty; 6–8” under drive lanes, loading zones, or frequent turns.

- Infill: well-graded crushed stone; compact each 4–6” lift to refusal; finish flush with cell tops.

- Blinding/interface: 20–40 mm sand/fines choke layer so cement paste doesn’t drain into cells.

- Anchoring: pins at perimeters, corners, curves; tighten spacing at transitions and crowns.

- Joints: saw-cut spacing and layout per slab thickness and climate; seal where needed.

- Drainage: edge drains or outlets; keep slab edges from trapping water.

- Edges/tie-ins: tuck geocell 150–300 mm under adjacent pavements to prevent edge shoving.

Step-by-Step: Pouring Concrete Over a Geocell Grid

1) Subgrade & Separator

- Strip organics/soft spots, grade to crossfall, compact to spec.

- Place nonwoven geotextile with 150–300 mm overlaps; keep it flat and wrinkle-free.

2) Deploy the Geocell Ground Grid

- Expand panels square to traffic; connect sheets (keys/clips/UV-ties).

- Anchor per spec—perimeter first, then field (≈0.9–1.5 m spacing typical).

3) Infill & Compact

- Place graded aggregate in 4–6” lifts; compact each lift.

- Finish flush with the cell walls—no overfill mounds.

4) Blinding Layer

- Spread 20–40 mm of sand/fines and lightly compact. This prevents paste loss and yields a smooth platform.

5) Form, Reinforce, Pour

- Set forms, place steel or fibers, verify cover.

- Pour concrete, strike off, finish per slip/skid requirements.

6) Cure & Cut

- Cure as specified.

- Saw-cut joints on schedule (and pattern) to control cracking; seal if required.

Geocell Driveways: Concrete vs. Gravel Surfaces

If U’re weighing a hard surface against a confined aggregate surface:

- Concrete over geocell driveway: clean finish, snow-plow friendly, high stiffness, excellent for turning areas.

- Confined aggregate option (no concrete): a gravel driveway grid (a.k.a. driveway gravel mesh) keeps stone locked, drains freely, and lowers upfront cost; add a thin choke for a smooth ride.

Geocell driveway cost: total cost depends on subgrade condition (undercut/working layer), cell height, infill gradation, slab thickness/jointing, drainage, and edges. The geocell layer typically reduces base depth and trucking, which offsets part of the slab cost. For budgeting, model both scenarios (concrete over geocell ground grid vs. confined aggregate only) and compare lifecycle: maintenance, snow operations, and rut repairs.

Common Mistakes (and Fast Fixes)

- Skipping the geotextile → fines pumping. Fix: install full-footprint separator with overlaps.

- Under-anchoring the grid → panel creep at edges/curves. Fix: tighten pin pattern, especially at perimeters.

- Overfilling cells → shoving/washboarding under the slab. Fix: finish flush, then apply a thin blinding layer.

- No drainage plan → edge saturation, freeze-thaw damage. Fix: provide outlets, maintain crossfall, protect edges.

- Late saw-cuts → random cracking. Fix: cut on time and to the correct depth.

FAQs

Will concrete paste fill the geocell cells?

Not if U use a compacted flush infill plus a blinding layer; that interface stops paste migration.

Does geocell replace reinforcement?

No. The geocell grid improves the foundation modulus. Reinforcement/joints are still engineered per slab design.

Can I use fibers instead of mesh?

Often yes for shrinkage control, but follow the pavement engineer’s design and the project spec.

Procurement Notes

- Specify UV-stabilized HDPE, cell height, weld strength, expanded area, and QA docs.

- Order connectors/keys, anchors, nonwoven geotextile, and edge restraints with the geo cell grid.

- Request a method statement and take-off based on expanded coverage so quantities land right the first time.

Conclusion

U can pour concrete over a geocell ground grid—and in many drive lanes and pads, U should. The recipe is straightforward: compacted subgrade, full-footprint separator, correctly anchored geo cell ground grid, dense aggregate infill flush to cell tops, a thin blinding layer, then the slab with proper joints and drainage. Whether U choose a finished concrete geocell driveway or a confined-aggregate gravel driveway grid, geocell confinement lowers risk, stabilizes weak soils, and delivers predictable performance—with a clearer path to controlling geocell driveway cost from bid to maintenance.