How does geogrid work for your infrastructure projects?

Are you frustrated by ground sinking or soil shifting on your project site? Do you worry about expensive rework because the foundation failed? I know how it feels when the earth moves unexpectedly.

Geogrid works through mechanical interlock to stabilize soil. It creates a stiff layer that spreads heavy loads across a wide area. This prevents lateral movement and ensures your project foundation stays strong and safe for many years.

I want to help you understand this material from a factory point of view. I have spent years in our MJY facility watching these grids come off the production lines. If you stay with me, I will show you how to choose and use geogrid to save money and time.

What is geogrid?

Do you sometimes find that standard soil cannot support the heavy machinery on your site? This problem often leads to deep ruts or structural cracks. It is a common headache for every construction buyer and wholesaler.

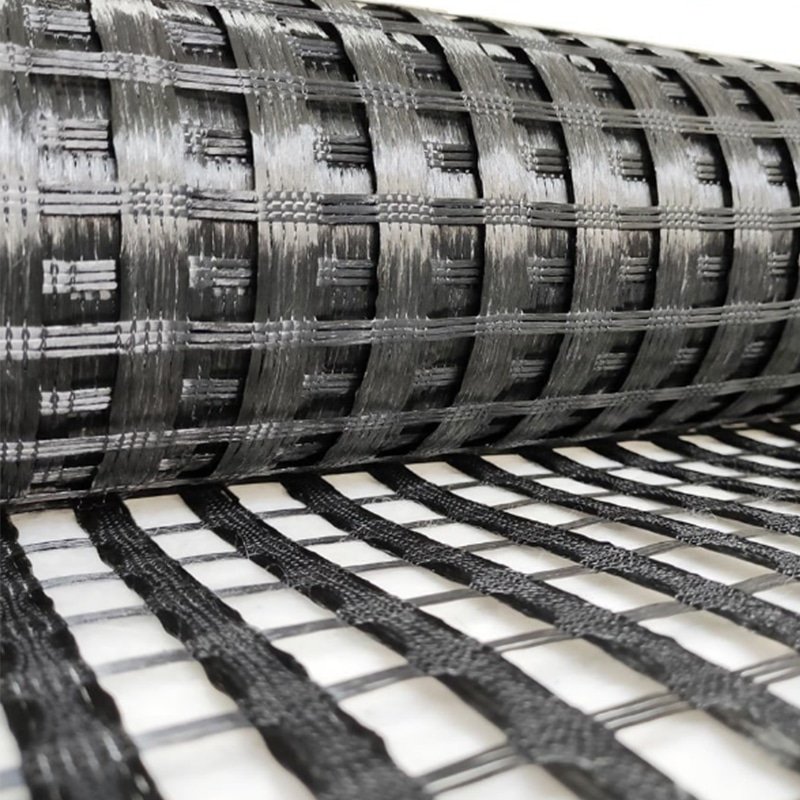

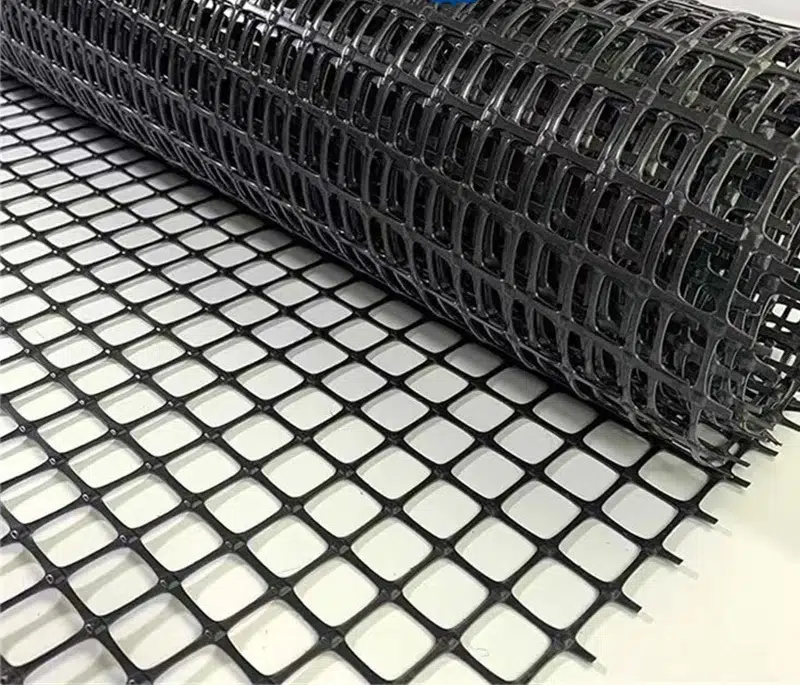

What is geogrid is a question I answer every day at our factory. It is a geosynthetic material made from high-strength polymers like HDPE or polyester. It has large open holes called apertures that allow soil and rock to lock firmly into the mesh.

I see our machines stretching these materials every day to make them strong. We start with a solid sheet of polymer. We punch holes in it. Then we stretch it under high heat. This stretching aligns the molecules. It turns a simple piece of plastic into a high-performance structural grid. I remember a client from Malaysia who visited our 300,000 square meter plant. He was amazed at how a grid could be so stiff. He needed it for a project where the soil was very soft and wet.

Understanding geogrid types and materials

You need to know that not all grids are the same. We manufacture three main types at MJY. Each one has a specific job. If you use the wrong one, your project might fail. I always tell my buyers to check the project specs before they order.

| Grid Type | Strength Direction | Best Use Case |

|---|---|---|

| Uniaxial | One direction | Retaining walls and slopes |

| Biaxial | Two directions | Road bases and foundations |

| Triaxial | Multi-directional | Heavy industrial yards |

If you are building a geogrid retaining wall, you must use a uniaxial grid. This grid is very strong along its length. It acts like a long anchor that goes deep into the soil behind the wall. It holds the weight of the earth. If you use a biaxial grid for a tall wall, it might not have enough pull-strength. This is a critical technical point. I have seen projects where the wrong material was used and the wall started to tilt. It is very expensive to fix a tilting wall.

We also focus on the polymer quality. We use 100% virgin resin. Some cheap factories use recycled plastic. Recycled plastic breaks down faster in the ground. It cannot handle the chemicals in the soil. I always show our ISO certificates to our partners. I want them to know that our ribs and junctions are built to last. The junction is where the ribs cross. It must be strong enough to transfer the load. If the junction breaks, the whole grid becomes useless.

How to install geogrid?

Have you ever seen a road start to crack just a few months after it was finished? It is a nightmare for the contractor and the government. Most of the time, the problem is not the material but how it was put in the ground.

How to install geogrid is a simple process but it requires focus. You must prepare the subgrade, unroll the grid flat, pull it tight to create tension, and then cover it with the right amount of aggregate before driving on it.

I have talked to many engineers about installation. They tell me that tension is the secret. If the geogrid is loose or wavy, it will not work. It must be pulled taut. Think of it like a guitar string. It only works when it is tight. I saw a project once where the workers just tossed the grid on the ground and dumped rock on it. That road had ruts within a week. The grid did not engage because it was not tight. You must use pins or staples to hold the grid in place.

Steps for a successful installation

I always provide an installation guide with every shipment from our factory. I want my customers to succeed. If their project looks good, they will come back to MJY for the next one. This is how we build long-term trust.

| Installation Step | Key Action | Why it matters |

|---|---|---|

| Site Preparation | Level the ground | Prevents punctures in the grid |

| Placement | Overlap the edges | Ensures no weak spots in the base |

| Tensioning | Pull the grid flat | Activates the mechanical interlock |

| Backfilling | Minimum 15-20cm cover | Protects the ribs from heavy tires |

When you lay the grid, the overlap is very important. I recommend at least 30 centimeters of overlap. If the soil is very soft, you might need 50 centimeters. You should never drive heavy trucks directly on the geogrid. You must spread the rock in front of the truck. This layer of rock protects the polymer ribs. If you crush the ribs with a truck tire before the rock is down, you destroy the strength of the grid. I tell my workers in the factory to pack the rolls carefully so they do not get damaged during shipping. We want the material to arrive at your site in perfect condition.

Another thing to remember is the aggregate size. The stones you use should be slightly larger than the geogrid apertures. This allows the stones to lock into the holes. If the stones are too small, they will just slide through the grid. If they are too big, they will not seat correctly. This balance is what creates the stiff mattress effect. I have seen contractors use the wrong stone and the grid just sits there without doing any work. It is a waste of money and material.

Why choose geogrid for your projects?

Do you feel like you are spending too much money on gravel and stone for your road bases? Buying thousands of tons of rock is a huge part of your budget. I know that cost control is vital for every wholesaler and project manager.

Geogrid provides a cost-effective solution by reducing the required aggregate thickness by up to 50%. It increases the bearing capacity of soft soils and extends the service life of roads and walls by preventing lateral spreading.

I often talk to buyers like Thang about the long-term value. Some people only look at the price of the roll. They do not see the total project cost. If you use our high-quality geogrid, you can buy much less stone. You save money on the stone itself. You also save money on the trucks used to haul the stone. You save money on the fuel and the labor. When you add it all up, the geogrid pays for itself. This is what I mean by long-term value.

Financial and structural advantages

In my 15 years in this industry, I have seen many changes. But the need for a solid foundation never changes. We focus on making products that give you an advantage in the market. If you are a wholesaler, you want a product that your customers can trust.

| Benefit Category | Impact | Real-world result |

|---|---|---|

| Cost Savings | Less aggregate needed | Lower material and shipping fees |

| Time Savings | Faster installation | Projects finished ahead of schedule |

| Durability | Prevents rutting | Fewer repairs and lower maintenance |

| Performance | High load capacity | Can build on very soft or wet soil |

I believe that geogrid is an insurance policy for your project. If you are building a geogrid retaining wall, you are protecting the property for decades. A wall that fails is a disaster. It can destroy buildings or hurt people. That is why we are so strict about our production standards at MJY. We do not take shortcuts. We use advanced sensors on our 50 production lines to monitor the thickness and strength of every meter of grid. We want you to be confident when you tell your clients that the foundation is secure.

Wholesalers also like our products because they are easy to store and handle. We roll them tightly. We label them clearly. We provide all the technical data sheets you need for government bidding. I know that documentation is just as important as the material itself in large contracts. If you have the right papers and the right quality, you win the bid. My goal as the owner of MJY is to be the partner that helps you win those bids. We are more than just a factory; we are your technical support team.

FAQ

Can I use geogrid for a small driveway project? Yes. Geogrid is excellent for residential driveways. It prevents the gravel from sinking into the dirt over time. It keeps your driveway flat and prevents mud from coming to the surface after it rains.

Does geogrid work in freezing temperatures? Yes. Our geogrids are made from polymers that stay flexible even in cold weather. They do not become brittle or crack. We export a lot of material to cold regions in Northern Europe and North America.

What is the lifespan of geogrid in the ground? If you use high-quality HDPE or polyester grids from a reliable factory, they can last for over 75 years. They are resistant to biological attacks and common soil chemicals.

How do I know which aperture size to choose? You should match the aperture size to the size of your aggregate. Your engineer will usually specify this. If you are not sure, you can send us your stone samples and our technicians will recommend the best grid.

Conclusion

Geogrid is a powerful tool for stabilizing soil and saving project costs. It ensures your infrastructure stays strong for many decades.