What Is Geogrid?

If you’re dealing with sinking driveways, soft subgrade, or leaning retaining walls, geogrid is one of the most effective tools you can put in the ground.

Simple Definition: How Geogrid Works

A geogrid is a grid-shaped, high‑strength plastic mesh that you place in soil or aggregate to reinforce and stabilize it.

In plain language:

- The soil provides weight, and

- The geogrid provides strength and tension,

so together they act like one reinforced soil mass instead of loose, shifting ground.

Engineers call this geogrid soil reinforcement or geosynthetic soil reinforcement.

How Geogrid Fits Into Soil Reinforcement and Stabilization

You use geogrid when soil alone is not strong enough to handle loads or slopes, for example:

- Driveways and roads over weak subgrade

- Retaining walls and steep slopes

- Parking lots, yards, and heavy equipment pads

Geogrid works by:

- Locking aggregate and soil into its openings (apertures)

- Providing lateral restraint, so particles can’t spread out under load

- Spreading loads over a wider area, reducing pressure on soft subgrade

That’s the core soil stabilization mechanism behind how geogrid works.

Basic Components: Ribs, Junctions, and Apertures

Every geogrid, whether uniaxial, biaxial, or triaxial, is built from three key parts:

- Ribs – The long and cross bars of the grid that carry tension.

- Junctions (nodes) – The connection points where ribs meet; they transfer load between ribs and keep the grid acting as one unit.

- Apertures – The openings between ribs. These are critical for particle interlock and aperture interlock, where soil and aggregate “key” into the grid.

The shape and size of the apertures are not cosmetic. They directly affect:

- How well the geogrid grabs aggregate

- How effectively it distributes loads

- How much lateral restraint it provides

Geogrid vs Geotextile: Why the Difference Matters

People often confuse geogrid with geotextile, but they do very different jobs:

| Feature | Geogrid | Geotextile |

|---|---|---|

| Structure | Open grid (ribs & apertures) | Continuous fabric (woven or nonwoven) |

| Main function | Reinforcement & stabilization | Separation, filtration, sometimes limited reinforcement |

| How it works | Interlock + lateral restraint + load spread | Acts like a barrier and filter |

| Best for | Retaining walls, base course stabilization, weak subgrade | Separating soil/aggregate, drainage layers |

If you need true reinforcement and load distribution in base courses or retaining wall backfill, geogrid is the primary tool, often used together with geotextile, not instead of it.

Common Polymer Materials Used in Geogrids

For the US market, quality geogrids are typically manufactured from durable polymers designed for long life in soil:

- Polypropylene (PP geogrid) – Common for biaxial and triaxial geogrids in road base reinforcement and base course stabilization. Good chemical resistance.

- High-Density Polyethylene (HDPE geogrid) – Often used where toughness, durability, and environmental resistance are critical.

- Polyester (PET geogrid) – Common in uniaxial geogrids for retaining wall reinforcement and slope stabilization geogrid applications, often coated for extra protection.

These polymers are chosen for:

- High tensile strength

- Creep resistance (holding strength over decades)

- Chemical, biological, and UV resistance once installed in soil

That combination is what allows a properly selected geogrid to keep working quietly underground for decades, supporting your walls, slopes, and pavements.

Types of Geogrid and How Each One Works

When we talk about how geogrid works, it really comes down to the grid direction, shape, and opening size. That’s what controls how loads move and how well the soil locks into the geogrid.

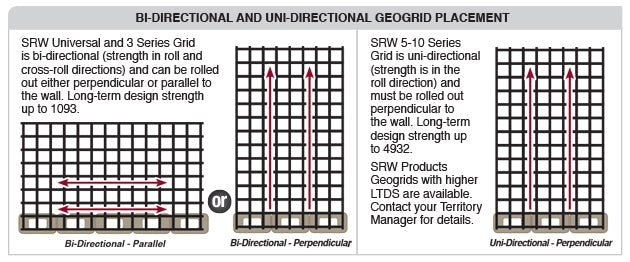

Uniaxial Geogrid: Strong in One Direction

Uniaxial geogrid is designed to be very strong in one main direction.

- How it works:

The ribs run in one primary direction, so it takes high tension in that direction and holds soil in place as it tries to pull away. - Best uses:

- Tall retaining walls

- Reinforced slopes

- Mechanically stabilized earth (MSE) structures

- Key point: You must install it with the strong direction perpendicular to the wall or slope face, so it can resist pullout.

Biaxial Geogrid: Load Spreading in Two Directions

Biaxial geogrid has similar strength in both the length and width.

- How it works:

It spreads loads both front-to-back and side-to-side, giving two‑directional load distribution and better particle interlock in the base layer. - Best uses:

- Driveways and access roads

- Parking lots and storage yards

- Base course stabilization over weak subgrade

- Key point: Ideal when traffic loads come from different directions and you want to cut down rutting and settlement.

Triaxial Geogrid: Multi‑Directional Performance

Triaxial geogrid uses a triangular or hexagonal pattern to deliver multi‑directional strength.

- How it works:

The triangular grid shape spreads forces in many directions, not just two. This boosts lateral restraint and improves performance under turning, braking, and wandering traffic. - Best uses:

- Heavily trafficked roads

- Industrial yards and ports

- Areas with mixed, variable loading

- Key point: If you’re dealing with high traffic and soft subgrades, a triaxial geogrid can give you a stiffer, longer‑lasting base. You can see how these work in more detail in our triaxial geogrid product overview.

Grid Shape and Aperture Size: Why They Matter

The grid shape (square, rectangular, triangular) and aperture size (opening size) are critical to how geogrid soil reinforcement performs.

- Grid shape:

- Squares/rectangles: good for basic road base reinforcement

- Triangles: excellent for multi‑directional traffic and load spread

- Aperture size:

- Openings must be large enough for the aggregate to sit inside the grid

- Too small: soil can’t properly interlock

- Too big: not enough confinement or lateral restraint

When aperture size matches your aggregate size, particle interlock is maximized and the geogrid works at full capacity.

Matching Geogrid Type to Soil and Loads

To decide which geogrid to use, I always look at three things: soil, load, and structure type.

- Soft, weak subgrade + vehicle traffic

- Use biaxial or triaxial geogrid for base course stabilization and better load distribution.

- Retaining walls and reinforced slopes

- Use uniaxial geogrid, oriented with the strong direction going back into the soil.

- High traffic, heavy loads, or turning movements

- Favor triaxial geogrid for superior multi‑directional stiffness and reduced rutting.

- Fine-grained or very soft soils

- Make sure the aperture size fits your chosen aggregate so you get solid interlock and confinement.

For projects that need higher long‑term tensile strength (especially walls and slopes), I often lean on polyester geogrids with strong coating systems, like those used in our polyester geogrid solutions for reinforced soil.

Core mechanics: how geogrid works in soil

Geogrid soil reinforcement in plain language

When people ask “how does geogrid work?”, the simple answer is:

geogrid locks into the soil and turns it into a stronger, more stable block.

Instead of letting soil move and spread out under load, geogrid grabs the soil, holds it in place, and spreads the pressure over a much larger area. That’s why geogrid soil reinforcement is so effective on weak subgrades, driveways, roads, retaining walls, and slopes.

Particle interlock: how soil keys into the apertures

The main mechanism is particle interlock:

- The open spaces in the grid are called apertures.

- When you place aggregate (gravel, crushed stone) over the geogrid and compact it, the rock pushes down into those apertures.

- The ribs and junctions of the geogrid grab the aggregate, like rebar grabbing concrete.

- Once locked in, the soil and geogrid move together as one reinforced layer.

With a well-designed biaxial geogrid or triaxial geogrid, the aperture size and shape are made specifically to get strong interlock with typical road base stone, which is why quality matters so much when you’re choosing a product.

Confinement and lateral restraint

Loose soil wants to spread sideways when it’s loaded. Geogrid stops that sideways movement.

- The grid provides lateral restraint: it resists the soil’s tendency to push out.

- This confinement keeps the aggregate tight and dense, so it stays stiff instead of pumping and rutting.

- The tighter the interlock, the better the confinement and the higher the effective stiffness of the whole base layer.

This is the core soil stabilization mechanism: restrain the soil laterally so the vertical loads don’t destroy the structure.

Load distribution over weak subgrade

On weak subgrade (soft clay, wet silts, organics), you don’t want wheel loads punching through. With geogrid for weak subgrade, the load gets spread out:

- The aggregate layer transfers load into the geogrid.

- The geogrid spreads that load over a wider area of subgrade.

- The pressure on any one point of the weak soil drops, so it doesn’t fail as quickly.

This load distribution geogrid effect is why you can often reduce base thickness and still handle the same traffic, especially when using engineered products like biaxial integral geogrid products.

Tensioned membrane effect under traffic

Under repeated truck or vehicle loads, geogrid starts acting like a tensioned membrane:

- The wheel load tries to push down, creating a small depression.

- As that happens, the geogrid develops tension from being stretched across the soft spot.

- That tension helps “hold up” the aggregate above, reducing rutting and long-term settlement.

This tension membrane effect is especially important in road base reinforcement, temporary access roads, and construction pads where the subgrade is very soft.

Turning loose soil into a reinforced soil mass

Think of it this way: without geogrid, your base is just a pile of rocks sitting on weak soil. With geosynthetic soil reinforcement:

- The rocks and grid are mechanically locked together.

- The soil mass behaves like a stiff, reinforced layer instead of a loose fill.

- The system gains strength in tension from the geogrid and strength in compression from the aggregate.

That composite behavior is what lets mechanically stabilized earth (MSE) walls, embankments, and road bases carry loads that plain soil cannot.

Simple real‑world analogies

To understand how a geogrid works, these analogies help:

- Rebar in concrete: Concrete is strong in compression, weak in tension. Rebar takes the tension.

Same idea with soil and geogrid—soil takes compression, geogrid takes tension. - Wire mesh under gravel: Imagine a heavy wire mesh under a gravel driveway. The mesh keeps the gravel from sliding sideways and spreading out. That’s similar to aperture interlock and lateral restraint.

- Snowshoes on soft snow: Snowshoes spread your weight out over a larger area so you don’t sink. Geogrid does this for vehicles on soft subgrade.

All of this is why, when someone asks “how geogrid works in soil?”, I tell them:

it locks into the aggregate, holds it in place, and spreads the load—turning weak ground into a stable, reinforced foundation.

How geogrid works in retaining walls and slopes

How does geogrid work in retaining walls (MSE walls)?

In a retaining wall, geogrid turns loose backfill into a single, solid block of mechanically stabilized earth (MSE).

Here’s the simple version of how geogrid works:

- The wall facing (blocks, panels, or baskets) holds the front.

- Layers of geogrid extend back into the soil behind the wall.

- Soil locks into the geogrid apertures (openings), creating particle interlock.

- The geogrid takes tension, the soil takes compression, and together they act like a reinforced block instead of loose dirt.

That reinforced soil mass is what actually holds back the ground, not just the blocks you see on the face.

Layered geogrid behind retaining walls

For most segmental retaining walls in the U.S., geogrid is installed in layers like this:

- Placed in horizontal layers behind the wall at set vertical spacing (commonly 8–24 in, depending on design).

- Each layer runs straight back into the slope—often 60–100% of wall height in length.

- The soil is compacted over each geogrid layer to get strong interlock and confinement.

Key points:

- More wall height = longer geogrid lengths and usually more layers.

- Proper compaction around the geogrid is what makes the system work.

Connection between geogrid and wall face

The way geogrid connects to the wall face is a big deal for performance:

- With concrete blocks, geogrid is usually sandwiched between block courses and held by the block weight and batter.

- With panel systems, geogrid often clips or pins into connection hardware built into the panels.

- With gabion or welded wire, the grid ties into the baskets or mesh.

That connection lets the facing and the geogrid act together, so the wall doesn’t just bulge at the front while the soil stays behind.

How geogrid helps build taller and steeper walls safely

Because geogrid creates a reinforced soil mass, you can:

- Build taller walls without needing a massive concrete gravity wall.

- Go near vertical or very steep (up to 70–80° or more with the right design).

- Reduce excavation compared with thick gravity walls.

Typical U.S. applications:

- Residential and commercial tiered retaining walls

- DOT highway and ramp MSE walls

- Bridge abutments and approach fills

When walls get high (say 6–8 ft and up), you absolutely want engineered geogrid design, not just stacked blocks.

How geogrid works on slopes (sliding and erosion control)

On slopes, geogrid soil reinforcement helps resist sliding and surface erosion:

- The geogrid forms a reinforced mat inside the slope.

- Soil keys into the apertures, so the grid provides lateral restraint.

- This helps stop the upper soil layers from creeping downhill over time.

- With topsoil and vegetation, roots grow through the grid, creating an even stronger reinforced layer.

Typical uses:

- Steep roadside embankments

- Residential yard slopes behind houses

- Landfill and detention pond side slopes

For surface protection only, people sometimes use geotextiles or erosion blankets, which is a different product. (If you’re unsure about the difference, it helps to first understand what geotextile fabric is used for.)

Real‑world examples of geogrid‑reinforced walls and embankments

You’ll see how geogrid works in soil every day in the U.S., even if you don’t notice it:

- Highway MSE walls supporting overpasses and ramps

- Rail embankments carrying heavy axle loads on soft ground

- Big box store parking lots with tall retaining walls at the edges

- Residential subdivisions where backyards are held up by segmental retaining walls

- Industrial yards with steep reinforced embankments around loading areas

In all these cases, the visible wall or slope face is just the skin. The real strength comes from the geogrid layers inside the soil, creating a stable, engineered structure that holds up over decades.

How Geogrid Works in Base Stabilization and Pavements

Using geogrid over weak subgrade for driveways and roads

When you build a driveway or road over soft, pumping, or clayey subgrade, geogrid works like a reinforcing mesh that turns that weak base into a stronger platform. The stone base locks into the grid openings (apertures), so instead of the rock punching down into the mud, the geogrid spreads the load out over a wider area. For residential driveways, farm lanes, and access roads, this usually means less mud, fewer soft spots, and a surface that actually holds up under real traffic.

Base course stabilization under asphalt and pavers

In paved systems, geogrid sits in or just under the base course under asphalt, concrete pavers, or gravel surfaces. Once compacted, the aggregate and the grid act together as a reinforced base layer. That base resists lateral movement, so ruts and dips don’t form as quickly. If you’re looking at a driveway application, it’s worth checking out how a dedicated geogrid for driveways is designed to lock up with typical road base stone used across the U.S.

Reducing aggregate thickness with geogrid reinforcement

Because geogrid strengthens the base, you can often reduce the base stone thickness while getting the same or better performance. That means:

- Less excavation

- Less imported aggregate

- Faster install times

For many light- and medium-duty projects in the U.S. (driveways, parking pads, farm roads), geogrid lets you build a stronger section without overbuilding the stone layer.

Cutting down rutting and settlement under traffic

Under repeated car and truck loads, unreinforced gravel wants to shove sideways and sink. With geogrid:

- The aggregate is confined in the apertures (particle interlock).

- The base resists lateral spread.

- Loads get carried like a tensioned membrane, reducing deep ruts and long-term settlement.

You’ll see this benefit most on gravel driveways, suburban streets, RV parking, and loading areas where wheel paths usually rut out first.

Improving bearing capacity for heavy loads and equipment

On weak subgrades, installing geogrid under the base increases the effective bearing capacity of the ground. That’s especially valuable for:

- Heavy trucks and trailers

- Construction equipment

- Farm and ranch gear

- Fire lanes and service roads

Instead of single axles punching through, the geogrid spreads that wheel load out, so the subgrade “feels” a much lighter pressure.

Using geogrid for parking lots, yards, and temporary roads

For parking lots, storage yards, and temporary access roads, geogrid helps you get more performance out of a thinner, cheaper section. Typical uses across the U.S. include:

- Gravel employee parking lots and overflow parking

- Equipment and container yards

- Oilfield, wind farm, and utility access roads

- Temporary construction entrances and haul roads

By reinforcing the base course, geogrid keeps surfaces usable longer and reduces how often you need to re-grade and add rock—major savings over the life of the project.

Key benefits: how geogrid works in soil reinforcement

Cost savings: thinner sections, less excavation

When you understand how geogrid works, you can start cutting costs right away:

- Thinner base sections – Geogrid soil reinforcement lets you use less aggregate while still carrying the same loads. For driveways, parking lots, and access roads, that often means several inches less stone.

- Less excavation and haul‑off – Because you’re not digging as deep, you save on trucking, fuel, and disposal fees.

- Faster construction – Crews place grid and stone faster than over‑excavating and rebuilding a thick section.

In a lot of real U.S. jobs, this adds up to thousands of dollars saved on even small projects.

Long‑term performance & lower maintenance

How does geogrid work over the long haul? It keeps the base locked in place so it doesn’t pump, rut, or wander:

- Reduced rutting and settlement under repeated traffic

- Fewer callbacks for regrading gravel or patching asphalt

- More stable paver systems with fewer dips and trip hazards

You’re paying once for reinforcement instead of paying over and over for repairs.

Durability in soil: chemical, UV, biological

Quality geogrids made from polypropylene, HDPE, or polyester are built to last once they’re buried:

- Resistant to most soil chemicals and road salts

- Protected from UV once covered with aggregate or soil

- Unaffected by bacteria, fungi, and typical soil biology

If you’re using other geosynthetics on the same job, like a PP non‑woven geotextile under the geogrid, you’re building a full system that’s designed to perform for decades.

Environmental benefits: less aggregate, lower CO₂

Geogrid soil reinforcement isn’t just a performance move; it’s a sustainability move:

- Less aggregate mined, processed, and hauled

- Thinner pavement sections = lower cement and asphalt use

- Fewer repairs = less material and fuel over the life of the project

For U.S. contractors and owners focused on ESG or green building, geogrid is a simple way to cut the project’s carbon footprint.

Strong performance in soft soils, frost, and seismic areas

Geogrid shines where ground conditions are tough:

- Soft, wet subgrades – Interlock and lateral restraint stiffen the base and boost bearing capacity.

- Frost‑prone regions – A reinforced base holds together better during freeze–thaw cycles and spring thaw.

- Seismic zones – In mechanically stabilized earth (MSE) systems, geogrid helps soil act as a reinforced block that moves together instead of breaking apart.

That’s a big reason U.S. DOTs and engineers specify geogrid for highways, embankments, and heavy‑duty yards.

When geogrid beats traditional methods

There are plenty of cases where geogrid outperforms just “more rock” or thicker concrete:

- Weak subgrades where endless stone still ruts and pumps

- Remote or tight sites where hauling tons of extra aggregate is expensive

- Heavy truck traffic, container yards, and industrial slabs

- Steep retaining walls and slopes where soil alone can’t stand up

In short, when you need better performance from the same or weaker ground, geogrid soil reinforcement is usually the smarter, cheaper, and more durable answer.

Installation Best Practices: How Geogrid Works Best in the Field

Site prep: grading, compaction, and subgrade checks

If you want geogrid soil reinforcement to actually work, your base prep matters more than the grid itself.

- Strip organics and mud – Remove topsoil, roots, and soft muck. Geogrid over trash subgrade won’t save the job.

- Rough grade to design elevation – Keep the surface smooth, no sharp humps or dips.

- Proof-roll the subgrade – Run a loaded truck or roller over it:

- Pumping or deep ruts = subgrade is too soft

- Fix with undercut, thicker base, or additional geogrid layers

- Compact to spec – Usually 90–95% of standard Proctor for driveways and base course stabilization.

- Check moisture – Too wet = pumping and weaving; too dry = poor compaction.

If you’re also using a separator/filter like a geotextile under your grid, choose the right type (woven vs nonwoven) and install it flat without wrinkles. This guide on woven vs nonwoven geotextile performance is a good baseline when you’re designing layered systems.

How to place, overlap, and align geogrid correctly

How does geogrid work properly? By being installed tight and in the right direction.

- Roll direction matters

- For uniaxial geogrid, the strong direction runs perpendicular to the wall face or slope.

- For biaxial/triaxial geogrid, align rolls along the main traffic or load path.

- Lay it flat and tight – No waves, folds, or bubbles. Pull it snug by hand or with light tension.

- Overlap correctly (typical rules of thumb—always follow the manufacturer’s data sheet):

- 1–3 ft overlaps end-to-end and side-by-side for base reinforcement

- Stagger overlaps so they don’t line up in one weak seam

- Secure as you go

- Use stakes, pins, or small piles of aggregate on the edges and overlaps

- Don’t drive stakes through key junctions if it can be avoided

Getting proper interlock with the aggregate layer

Geogrid works because of particle interlock and lateral restraint, not just because it’s there.

To get good interlock:

- Use well-graded, angular aggregate (like crushed stone), not round pea gravel.

- Minimum cover: usually 6–8 in of aggregate above the grid for driveways and roads.

- Place aggregate in thin lifts (4–8 in), then compact each lift before adding more.

- Avoid dropping rock directly from high dump bed heights onto exposed grid—this can tear ribs and damage junctions.

When the stone locks into the apertures, you get true geogrid soil reinforcement: the grid and stone act as a single, stiff layer that spreads loads over weak subgrade.

Compaction tips to avoid damaging the geogrid

Compaction is where many contractors accidentally kill the performance of geogrid.

- Never compact directly on bare geogrid. Always have a cushion layer of stone over it first.

- Use the right equipment:

- Small to medium vibratory rollers or plate compactors for early lifts

- Heavier rollers only after you have enough cover

- First pass: low vibration or static until you’ve got at least a few inches of stone locked in.

- Turn equipment slowly to avoid scuffing or dragging the aggregate and grid.

If you see ripped ribs, pulled overlaps, or grid exposed after compaction, stop and fix it before building up.

Common geogrid installation mistakes to avoid

Here’s where most DIY and even some pros go wrong with geogrid for driveways, roads, and retaining walls:

- Laying grid directly on soft, un-compacted, or organic subgrade

- Using round gravel that can’t interlock with the apertures

- No overlaps or overlaps that are too small

- Wrong direction for uniaxial geogrid in retaining wall reinforcement

- Covering the grid with thick, uncompacted dumps of stone in one go

- Running heavy equipment directly on exposed grid

- Not tying geogrid properly into wall blocks or facing units

Any of these can cut performance in half or worse, even if you used a strong product.

Simple checks to see if your geogrid system is working

You don’t need a lab to see whether your geogrid installation is doing its job:

- Visual inspection while building

- Grid is flat and tight, no big wrinkles

- Overlaps are correct and well covered

- No visible tears or holes after backfilling and compaction

- Performance over time

- For base stabilization:

- Reduced rutting in driveways and parking lots

- Less settlement over soft spots or old fill

- For retaining walls and slopes:

- No bulging of the face

- No cracking, tilting, or excessive movement

- For base stabilization:

If you see early rutting, pumping, or wall bowing, something is off—usually subgrade prep, wrong aggregate, bad compaction, or poor grid layout. That’s when it’s worth looping in a geogrid manufacturer or engineer to review the installation and design.

How to choose the right geogrid for your project

Choosing the right geogrid is all about matching the product to your loads, soil, and layout. If you get those three right, the system will perform and last.

Match geogrid strength to loads and traffic

For US driveways, roads, parking lots, and yards, I look at:

- Traffic type:

- Light cars / pickup trucks → standard strength biaxial or triaxial geogrid

- Heavy trucks, forklifts, container yards → higher‑strength geogrid with proven lab test data

- Traffic frequency:

- Occasional use (farm lane, RV pad) vs. daily commercial traffic

- Design life:

- Temporary access road vs. long‑term public or industrial road

In simple terms: heavier and more frequent traffic = higher tensile strength and stiffness required.

Consider soil type, moisture, and subgrade

Your subgrade is just as important as the grid:

- Soft clays / silts (low CBR, “mushy” when wet):

- Use stiffer biaxial or triaxial geogrid with good aperture interlock

- You may need multiple layers if the subgrade is very weak

- Sand and granular soils:

- Biaxial or triaxial geogrid works well for load spread and lateral restraint

- High moisture / poor drainage:

- Plan for water: thicker base, drainage, and geogrid with good durability in wet conditions

If the subgrade pumps under light compaction, I always treat it as weak subgrade and size the geogrid and base accordingly.

Uniaxial vs biaxial vs triaxial geogrid

Use the grid form that fits the way your structure works:

- Uniaxial geogrid

- Strong mainly in one direction

- Best for retaining walls and steep slopes, where pullout forces act perpendicular to the wall

- Biaxial geogrid

- Strength in two main directions (X and Y)

- Common for road base reinforcement, driveways, and parking lots

- Triaxial geogrid

- Multi‑directional strength (triangular apertures)

- Great for traffic areas with turning, braking, and wander lanes

For retaining walls, I almost always go uniaxial. For base course stabilization and pavements, biaxial or triaxial is the go‑to.

How to read geogrid data sheets the right way

When I review a product data sheet, I focus on:

- Tensile strength (kN/m or lb/ft) at specified strain

- Junction strength (how strong the nodes are)

- Creep / long‑term design strength (especially for walls and slopes)

- Aperture size and shape (must match your aggregate size for good particle interlock)

- Durability data for chemical, biological, and environmental resistance

Don’t just compare “ultimate strength.” For real projects, long‑term design strength and stiffness matter more.

Why geogrid quality and standards matter

Not all geogrids are equal. In the US market, I always check that products:

- Are tested to recognized standards (ASTM, ISO, or relevant geosynthetic standards)

- Have traceable quality control and consistent roll‑to‑roll performance

- Come with design values, not just marketing numbers

Cheaper, untested grid might look similar, but if junctions are weak or creep is high, your wall or road can fail early. Quality control is non‑negotiable.

When to talk to a geogrid manufacturer or engineer

Bring in a pro when:

- You’re building a retaining wall over 4 ft (most US codes require engineering)

- The subgrade is very soft or saturated

- You’re dealing with heavy truck traffic, loading yards, or industrial floors

- You’re unsure about layer spacing, embedment length, or section thickness

For retaining wall builds specifically, a good next step is to follow a detailed guide on how to install geogrid for a retaining wall from a technical manufacturer resource, which walks you through wall height, spacing, and connection details: how to install geogrid for retaining wall.

If you’re still unsure after looking at the data sheet, reach out to the geogrid manufacturer or a local geotechnical engineer. A quick review up front is much cheaper than fixing a failed wall or rutted driveway later.

FAQs: How Geogrid Works (Straight Answers)

What’s the difference between uniaxial and biaxial geogrid?

| Type | Main Strength Direction | Best Use Cases |

|---|---|---|

| Uniaxial | One direction (length) | Retaining walls, tall slopes, MSE structures |

| Biaxial | Two directions (length + width) | Driveways, roads, parking lots, base stabilization |

- Uniaxial geogrid is designed to take high pull‑out forces in one direction, perfect when the load is mainly pushing out from a wall or slope.

- Biaxial geogrid spreads loads both ways, which is what you want under roads, driveways, and yards.

How deep and how often should I install geogrid layers?

It depends on what you’re building, but here’s a quick guide:

| Application | Typical Depth / Spacing (General Rule of Thumb) |

|---|---|

| Driveways / small roads | 8″–18″ base over geogrid |

| Segmental retaining walls | Geogrid every 2–3 courses (usually 16″–24″ vertical) |

| Slopes / embankments | Spacing based on slope height & angle (get design) |

For driveways, we often size base thickness and geogrid depth similar to what’s explained in this guide to how deep the base should be for a geogrid driveway at geosyntheticsmanufacturer.com.

Can geogrid replace concrete or other structures?

- No, geogrid does not replace concrete, footings, or engineered walls.

- Geogrid is soil reinforcement, not a structural frame.

- It works with:

- Segmental retaining wall blocks

- Concrete pavements

- Asphalt, pavers, or gravel surfaces

Think of geogrid as the “rebar for soil,” not a stand‑alone structure.

How long does geogrid last once it’s buried?

- Quality polypropylene, HDPE, or polyester geogrids are designed for 50–100+ years in soil when properly selected and installed.

- Buried geogrid is protected from UV and weather, which is why it lasts so long.

- Check:

- Creep resistance

- Chemical resistance

- Durability testing on the product data sheet.

Is geogrid suitable for DIY retaining walls and driveways?

Yes, for small residential projects, if you stay within reasonable limits:

Good DIY uses:

- Driveways and parking pads over soft spots

- Low retaining walls (often under 4 ft, depending on local code)

- Garden walls and landscape terraces

Key tips:

- Follow manufacturer spacing and embedment lengths.

- Use proper base prep, compaction, and backfill.

- For first‑timers, I’d follow a step‑by‑step guide like this one on how to install geogrid from geosyntheticsmanufacturer.com.

When should you NOT use geogrid without expert design?

Get an engineer or geogrid manufacturer involved if:

- Retaining walls are over 4 ft or carry traffic / buildings above.

- Slopes are steep (2H:1V or steeper) or very high.

- You’re dealing with very soft soils, wetlands, or organic muck.

- There’s heavy truck traffic, industrial loads, or cranes.

- You’re in seismic zones with tall walls or critical structures.

- There are drainage, erosion, or groundwater issues.

When in doubt, treat it like a structure, not just landscaping, and get a stamped design.