Top 5 Reasons to Choose a Geo Cell Grid for Soil Stabilization?

Muddy driveways and eroding slopes eat your budget and patience. Are you tired of constantly refilling gravel that just washes away in the next storm?

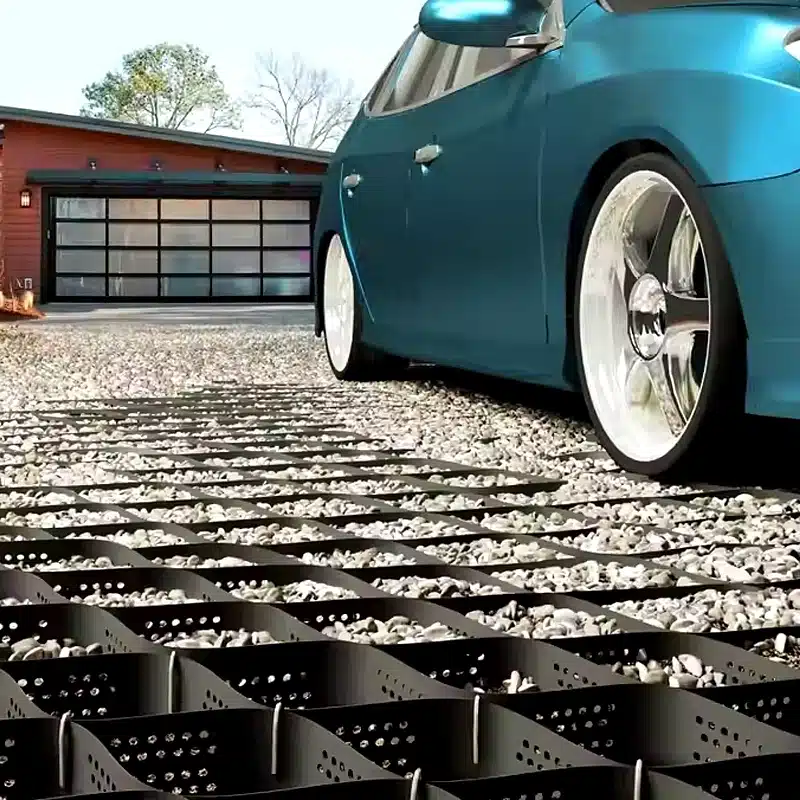

A geo cell grid is a 3D honeycomb structure made of HDPE that confines fill material. It stabilizes soil, prevents erosion, and increases load capacity by distributing weight. Choosing this system reduces maintenance costs and improves drainage for long-term project success.

Let’s look at why this material is replacing traditional concrete and loose gravel for buyers across the US.

What is a Geo Cell Grid?

You might be wondering, are they strong enough? Can they really withstand the weight of heavy trucks?

A geo cell grid is a cellular confinement system welded from high-density polyethylene strips. It holds stone, soil, or concrete in place to stop lateral movement. This structure transfers heavy vertical loads outward, effectively creating a semi-rigid mattress over soft subgrades.

Understanding the Factory Logic Behind the Geocell

The working principle of geogrids is confinement. When you dump gravel on the ground, the gravel spreads to the sides when a tire rolls over it. This is what causes rutting in pavements.

When you fill the same crushed stone into the geocell, the geocell walls push back, creating hoop stress. Unable to escape the pressure, the loose stones become a cohesive unit. As a purchasing agent or owner, this means you can use cheaper, locally sourced fill material to achieve the same strength as expensive paved surfaces.

We use virgin resin to ensure the plastic won’t crack in winter. When purchasing geocells, don’t just look at the unit price; you must also check the seam peel strength in the data sheet. High-quality geocells act like a flexible plate, bridging soft spots in the soil and distributing the weight of trucks over a larger area instead of concentrating it at a single point. Therefore, geocells are crucial for soft soil sites where heavy machinery might sink.

| Feature | Function | Benefit for Buyer |

|---|---|---|

| Ultrasonic Weld | Connects strips | Prevents cell bursting under load |

| Textured Surface | Increases friction | Keeps fill from sliding out |

| Perforations | Allow water flow | Prevents hydrostatic pressure buildup |

| Virgin HDPE | Material base | Ensures flexibility in freezing weather |

How does it improve load bearing capacity?

Soft ground sinks under heavy equipment, causing expensive ruts. How do you stop your project from failing under the weight of a delivery truck?

A geocell ground grid increases load-bearing capacity by up to 10 times compared to unconfined soil. The cell walls prevent the fill from spreading sideways. This allows you to build stable access roads or parking pads even on weak, muddy subgrades.

The Mechanics of Load Distribution

The biggest complaint I hear from clients regarding gravel roads is the constant maintenance. They fill a pothole, and a week later, it is back. This happens because the subgrade below the stone is soft. When a heavy wheel pushes down, the stone pushes out, and the mud pushes up. A geocell driveway solves this through what we call the beam effect.

Imagine the grid as a semi-rigid beam. When a load hits one cell, the grid transfers that force to the surrounding cells. Instead of 1000 pounds pressing down on one square inch of mud, that weight is spread over several square feet. This dramatically reduces the pressure on the subgrade. In my experience supplying materials for industrial yards, using a 6-inch deep grid can allow heavy rigs to drive over swampy land that would otherwise swallow a truck.

For the buyer, this translates to material savings. Without a grid, you might need to excavate 20 inches of soil and bring in expensive large rock to build a stable base. With a geo cell ground grid, you might only need 6 to 8 inches of aggregate to get the same support. You buy less stone, you truck in less material, and you dig less earth. It is a smarter way to engineer the ground. However, you must ensure the grid is expanded fully to its nominal size during installation to get this benefit. If the cells are oval, they are weak.

| Subgrade Condition | Traditional Gravel Depth | Geocell Gravel Depth | Material Savings |

|---|---|---|---|

| Firm Soil | 6 inches | 3-4 inches | 30% |

| Soft Clay | 12-14 inches | 6 inches | 50% |

| Silty/Wet Soil | 20+ inches | 8 inches | 60% |

| Peat/Mud | Unstable | 8-12 inches (with Geotextile) | High |

Can it solve your drainage problems?

Concrete pavements generate runoff, leading to standing water and flooding. Is there a way to have a paved surface that also provides excellent drainage?

Unlike asphalt, a geocell grid system is fully permeable. It allows rainwater to drain naturally through the infill and into the soil below. This reduces stormwater runoff issues and eliminates the need for complex, costly drainage infrastructure on your site.

Managing Water Flow and Hydrostatic Pressure

Water is the enemy of any pavement structure. In traditional road building, we try to seal the surface with asphalt to keep water out. But eventually, cracks form, water gets in, freezes, expands, and destroys the road. A geo cell grid takes the opposite approach.

By using open-graded aggregate (stones without fine dust) inside the cells, water flows straight through the surface. We manufacture the cell walls with perforations—tiny holes that allow water to move laterally between cells. This is crucial. If the water gets trapped in one cell, it can freeze and heave the ground. The holes ensure that water drains away quickly.

For residential buyers, this means no puddles on the driveway. For commercial developers, this is often a regulatory requirement. Many cities limit how much non-permeable surface (like concrete) you can have on a lot. A geocell system counts as permeable. You can maximize your building footprint while still meeting environmental codes. I always advise buyers to pair the grid with a non-woven geotextile underneath. This fabric acts as a filter, letting water pass into the earth while keeping your expensive stone from sinking into the mud.

| Surface Type | Permeability | Drainage Infrastructure Needed | Freeze/Thaw Risk |

|---|---|---|---|

| Concrete | None | High (Drains, Pipes) | High (Cracking) |

| Asphalt | Low | High (Sloping, Gutters) | High (Potholes) |

| Loose Gravel | High | Low | Medium (Washout) |

| Geocell Grid | Very High | Minimal | Low (Flexible) |

Is it really a cost-effective solution?

Construction budgets are tight, and material costs are rising. Are you spending too much on deep aggregate layers just to stabilize the ground?

Using a geo cell ground grid saves money by reducing the depth of aggregate needed by up to 50%. It also cuts long-term maintenance costs because you stop replacing washed-out stone. The installation is fast, reducing labor hours and equipment rental fees.

Analyzing the Total Cost of Ownership

When you look at the price tag of a pallet of geocell, it might seem like an added expense compared to just buying a truckload of gravel. But you have to look at the whole project. As a factory advisor, I help procurement teams run these numbers every day. The savings come from three buckets: aggregate reduction, installation speed, and long-term maintenance.

First, aggregate reduction. As we discussed, the grid allows you to use a thinner layer of stone. In many parts of the US, crushed stone is expensive to buy and expensive to truck in. Cutting that volume in half often pays for the grid immediately.

Second, installation. An enviro grid geo cell install is fast. The panels arrive collapsed and light. Two workers can expand a section covering hundreds of square feet in seconds. You do not need specialized heavy pavers or curing time like concrete.

Third, and most importantly, is maintenance. A standard gravel driveway needs topping up every spring because the snow plow scrapes it off or rain washes it away. With a grid, the stone is locked. It does not move. You might go 5 or 10 years without needing to buy more stone. When you factor in ten years of zero maintenance, the grid is significantly cheaper than any other option.

| Cost Component | Traditional Gravel Drive | Concrete Driveway | Geocell Driveway |

|---|---|---|---|

| Site Prep | Medium | High | Low |

| Material Cost | Low | High | Medium |

| Installation Time | Fast | Slow (Curing) | Fast |

| 10-Year Maintenance | High (Yearly Refills) | Low (Sealing/Crack fill) | Very Low |

What other applications does this technology have?

You might think this is only for driveways, but your site has other challenges. How do you handle steep slopes or muddy walking paths with one product?

Geocells are incredibly versatile. Beyond driveways, they are the standard for slope stabilization methods to prevent landslides. You can also use them as a turf reinforcement mesh for green fire lanes or overflow parking, giving you a green look with structural strength.

From Flat Roads to Steep Slopes

The versatility of this product comes from the infill. If you fill it with stone, it is a road. If you fill it with topsoil and seeds, it is a garden that trucks can drive on. I often see procurement lists that include geocells for multiple zones of a single project.

Let’s talk about slopes. Erosion control is a massive headache. Rain hits a slope, picks up speed, and washes the soil away. By pinning geocell panels to the slope, you create thousands of mini-dams. The water cannot build up speed, and the soil stays put. This is one of the most effective slope stabilization methods available. You can fill these cells with local soil and plant grass. The roots grow through the perforations, anchoring the grid to the hill.

Another growing application is the “invisible driveway.” Fire codes often require a wide lane for emergency trucks, but nobody wants a giant strip of asphalt ruining their garden design. You can use the grid as a turf reinforcement mesh. You fill it with soil and grass. The grid protects the root zone from being crushed by tires. To the eye, it looks like a lawn. To a fire truck, it is a stable road. When you select a grid for this, make sure to choose a cell height that matches your load requirements—usually 4 inches or more for vehicles.

| Application | Infill Material | Primary Function | Key Spec to Check |

|---|---|---|---|

| Driveway/Road | Angular Gravel | Load Support | Weld Strength |

| Slope Protection | Topsoil/Vegetation | Erosion Control | Anchor/Stake count |

| Channel Lining | Concrete | Hydraulic Flow | Surface Texture |

| Retaining Wall | Gravel/Soil | Earth Retention | Connection Clips |

Is this an eco-friendly choice?

Sustainability is a requirement for many modern bids. How do you reduce the environmental impact of your construction project without sacrificing quality?

A geo cell grid is an environmentally friendly choice. It creates permeable surfaces that recharge groundwater and reduce heat island effects. Because you use less mined aggregate and can use local fill, you significantly lower the carbon footprint of your supply chain.

Reducing Carbon Emissions in Construction

Sustainability is not just a buzzword; it is often a compliance issue. Factories like ours focus on producing HDPE grids that are chemically inert. This means they do not leach chemicals into the soil, which is vital for protecting local aquifers. HDPE is a durable polymer that resists UV degradation and chemical attacks, meaning it stays in the ground for decades without needing replacement.

The biggest environmental win, however, is logistics. Transporting heavy stone and concrete emits massive amounts of CO2. By using a geo cell ground grid, you use onsite soil or significantly less imported aggregate. This takes trucks off the road.

Furthermore, concrete and asphalt absorb heat, contributing to the “Urban Heat Island” effect. A grass-filled geocell surface stays cool. It absorbs rainwater rather than shedding it into storm drains. For buyers looking to meet LEED certification or local green building codes, this product is an easy win. It solves the structural problem while ticking the environmental boxes.

| Environmental Factor | Asphalt/Concrete | Geocell with Grass/Gravel |

|---|---|---|

| Water Runoff | 100% Runoff | <5% Runoff (Infiltration) |

| Heat Absorption | High (Heat Island) | Low (Cooling effect) |

| Material Transport | High Emissions | Reduced Emissions |

| Chemical Leaching | Potential (Bitumen) | None (Inert HDPE) |

Conclusion

A geo cell grid stabilizes soil, improves drainage, cuts costs, and protects the environment. It is the smart upgrade from loose gravel or expensive concrete.

Where to Buy Geocell? Contact MJY Geosynthetics for factory-direct quotes and technical guidance on your next project.