Where Are Geotextile Sandbags Commonly Used?

I see floods, scour, or weak banks stop a project fast. You want a simple, fast, and testable fix. Geotextile sandbags solve those urgent protection jobs without heavy concrete.

Geotextile sandbags protect slopes, rivers, coasts, and worksites by adding weight, filtration, and separation. They form temporary or semi-permanent structures that resist waves, flow, and erosion. They deploy fast, fit irregular ground, and use local sand or rock as fill.

You may need bags for flood defense this week, then a toe berm next month. I will walk through materials, typical applications, and quick design checks you can verify on site.

What Are the Common Materials Used to Make Geotextile Sandbags?

You want bags that hold shape, drain cleanly, and survive the sun. The polymer and fabric structure decide that. I match the bag type to the site load and fill.

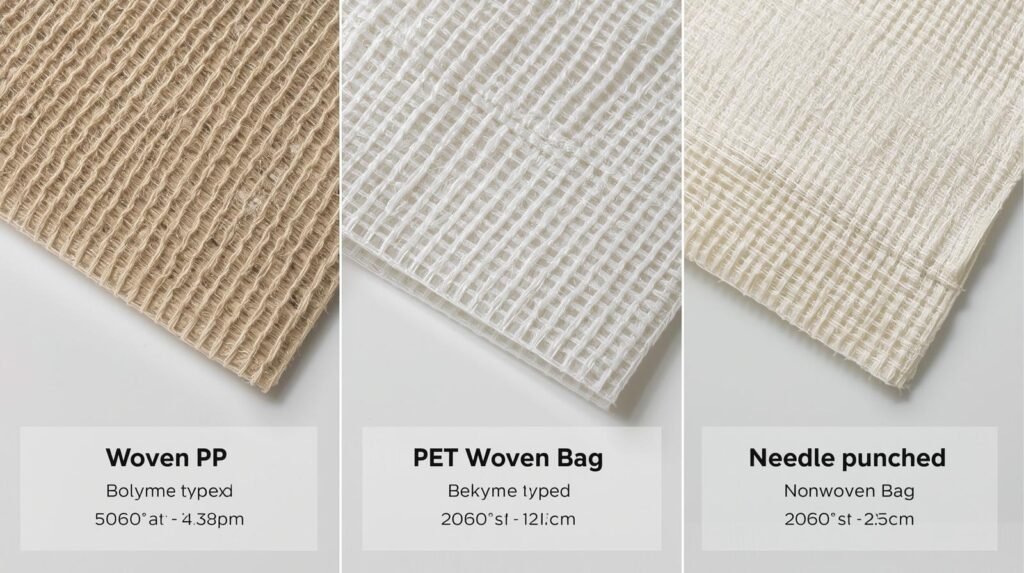

Most geotextile sandbags use polypropylene (PP) or polyester (PET). Woven PP gives high tensile and fast sewing. PET holds strength better at heat. Nonwoven needle-punched bags act like filters and cushions. Composites add coatings or layers when abrasion is high.

1) Polymer and fabric logic

I choose PP for chemical resistance, low density, and strong seams at a good cost. I choose PET when hot climates or long design life push creep and UV stability. Woven fabrics give clear strength directions and low stretch. Nonwoven fabrics give in-plane water paths and better filtration under fine soils. For fast flood response, a woven PP geotextile fabric bag sews fast and packs tight. For river silt and underlay functions, a nonwoven geotextile filter bag limits soil loss while letting water pass.

2) Stitching, closure, and handling

Thread must match the polymer and UV grade. Chain-stitch is fast for temporary works. Lock-stitch holds better for long service. I specify drawstrings or flap folds when crews wear gloves. Lift loops help with big geotextile bag handling by crane. Labels must show batch, polymer, and weight. This avoids mix-ups on line.

3) Fill choices and moisture

Local sand works in most jobs. River sand compacts well. Dry sand fills faster. If I expect vandalism or high energy waves, I use a geotextile rock bag with 10–50 mm stone. In dredging works, I may pump slurry into a geotextile form bag or a geotextile geo bag to dewater fines. When pore water is dirty, nonwoven helps hold fines better than a tight woven.

4) Quick compare

| Material option | Typical weight (gsm) | Strength style | Filtration role | Best quick uses |

|---|---|---|---|---|

| Woven PP | 120–250 | High tensile, low stretch | Limited, relies on seams | Flood berms, temporary training walls |

| Woven PET | 150–300 | Strong at heat, low creep | Limited | Hot climate, longer life works |

| Nonwoven PP/PET | 200–500 | Moderate tensile, high puncture | Good filtration, cushion | Toe filter, contact with fines |

| Composite (coated) | 250–600 | Abrasion-resistant | Controlled flow | Surf zones, high wear faces |

You may also hear trade phrases. A “geotextile sand bag” or “geotextile bag sand” means the same basic unit: a geotextile bag filled with sand. Some buyers ask for “geotextile material of sand bag” test sheets. I attach tensile (ISO 10319), puncture (EN ISO 12236), and UV exposure data with each lot.

Where Are Geotextile Sandbags Commonly Used?

You see fast water, edges washing out, and gear limits. Sandbags win because crews carry them by hand, set them fast, and shape them to the ground.

Geotextile sandbags work on rivers, coasts, worksites, and mines. They build toe berms, temporary walls, scour aprons, and dewatering cells. They also protect pipes and outfalls.

1) River and canal works

At river toes, I lay a starter row, then stagger courses. I point the long side into the flow. A nonwoven underlay may sit beneath to keep fines in place. For high velocity bends, I mix in geotextile rock bag units on the face. Rock adds abrasion resistance where waves or debris hit. For culvert outlets, I set a fan-shaped apron. I extend it to the hydraulic jump length. This cuts backward erosion.

2) Coastal dunes and revetments

On dunes, bags act as a sacrificial toe. I prefer woven PET where sun and heat run high. UV-stabilized fibers, heavier gsm, and dark pigments help. If the brief is temporary, I use woven PP. For surf zones, a composite or coated face reduces wear. I step the face and wrap corners tight. I add a buried key below beach level to lock the system.

3) Scour protection at structures

Bridge piers and abutments see complex flow. I use larger units or a big geotextile bag with crane lifts. I place them in a pre-dredged pocket. I check embedment and overlap. Where flow returns upward, I add a geotextile form bag filled with pumped sand-cement for extra weight, or I switch to a geotextile rock bag layer if needed.

4) Dewatering and sludge management

In mines and treatment plants, I use a geotextile geo bag as a dewatering cell. Slurry enters. Water exits through the fabric. Fines stay inside. Polymer aids boost capture. When the cake sets, I move or cut the unit. This supports phased cleanup without large basins.

5) Pipe ballast and outfall protection

Pipes need stable support and cover. I place shaped units as saddles. A geotextile filter bag can surround riprap at outfalls. It holds fines while the rock breaks flow energy. For underwater outfalls, divers handle small units by hand and set them with markers.

6) Quick selection map

| Environment | Primary function | Recommended bag | Fill | Notes |

|---|---|---|---|---|

| River bend toe | Erosion control | Woven PP/PET sandbags | Sand | Add nonwoven underlay |

| Bridge pier apron | Scour protection | Big geotextile bag | Sand or rock | Use crane lift |

| Coastal dune toe | Wave run-up | Composite or PET | Sand | UV-stabilized, darker color |

| Outfall plunge pool | Energy dissipation | Geotextile rock bag | 10–50 mm stone | Fan layout |

| Dewatering pad | Sludge volume cut | Geotextile geo bag | Slurry + polymer | Dewater in cycles |

| Temporary cofferdam | Dry work area | Woven PP units | Sand | Stagger seams, tie-backs |

On purchase orders, the same item appears under many names: geotextile bag, geotextile sand bag, geotextile fabric bag, geotextile filter bag, geotextile form bag, and geotextile rock bag. The site decides which name fits. The function stays clear: weight plus filtration plus speed.

FAQ

Q: How long do these bags last in the sun?

A: UV life depends on polymer, pigment, and gsm. Temporary flood bags may run one season. UV-stabilized PET or coated faces last much longer in exposed coastal jobs.

Q: Can I refill or reuse a unit?

A: Crews rarely refill on site. Stitch holes and wear points grow. I treat used bags as single-use unless the spec says otherwise.

Q: What fill is best for a geotextile bag sand application?

A: Clean, well-graded sand compacts and drains well. For heavy wear zones, use small stone and convert the unit to a geotextile rock bag.

Q: Do I need an underlay?

A: If the subgrade is fine or soft, yes. A nonwoven underlay reduces piping and holds fines under the bag stack.

Q: How do I size a big geotextile bag?

A: Base it on lift gear, flow forces, and footprint. Common volumes range from 0.5–2.0 m³. Heavier units need crane or excavator placement.

Q: Is a geotextile geo bag the same as a dewatering tube?

A: It is similar in function. The term often refers to pump-filled, large filter units for sludge dewatering and shoreline fills.

Q: What tests matter on the datasheet?

A: Tensile strength, seam strength, puncture, UV resistance, and permeability. Ask for ISO 10319, EN ISO 12236, and UV exposure data.

Q: Can I pump grout or mortar into a geotextile form bag?

A: Yes, if the fabric and seams suit the mix and pressure. Many form bags are purpose-built for pumped fill.

Conclusion

Pick polymer, fabric, and fill for the job. Lock edges, add underlay where fines move, and match bag size to handling gear for safe, fast installs.